Posa Fuel Carburetor | Posa Racing Carburetor | Posa Carburetor [SUBSCRIBE TO OUR DAILY EMAIL OR FOLLOW US ON FACEBOOK, TWITTER, YOUTUBE, and PINTEREST.]

HOW TO ADUST POSA STYLE CARBURETORS

POSA Style carburetors trace their history back to the late 60's and early 70's. One of the first carburetors of this style was the Lake Injector. Don't confuse the word "injector" with fuel injection, as these series of carburetors are not a fuel injector or fuel injector body. During this same time period the POSA carburetors were introduced. As the POSA is a casting and the Lakes was a machined product, the Lake soon disappeared as the POSA was less expensive, buy a large margin.

The POSA was originally sold for aircraft use by HAPI, Revmaster and Monnett Experimental Aircraft. A little later in history, Revmaster introduced the Revflow Carburetor which is a similar type carburetor also. It looks like it might be a modified Lectron Carburetor body, with their own casting on one side of it with mixture control built into it.

The newest version of the POSA is the Aero Carb. Where as the POSA was a casting, the Aero Carb is machined from a billet of aluminum. The operational principals of all 4 carbs (Lake, POSA, Revflow and Aero Carb) are identical with variations in mixture control and needle adjustments for setting the mixture

All of these carbs have different needles that are round but have a flat ground on one side that is also tapered. As the throttle is opened, the needle is pulled out of a fuel orifice with the slide, allowing more fuel to be pulled into the carburetor throat. It is imperative that the flat part of the needle always face into the back of the carburetor.

If the needle were allowed to rotate, the draw across the needle changes and less fuel is induced into the engine, causing an engine to run lean. Most manufacturers of this style carburetor send a number of different needles along with the carburetor. The needles have different flats ground along the taper, allowing more or less fuel to be induced to the engine.

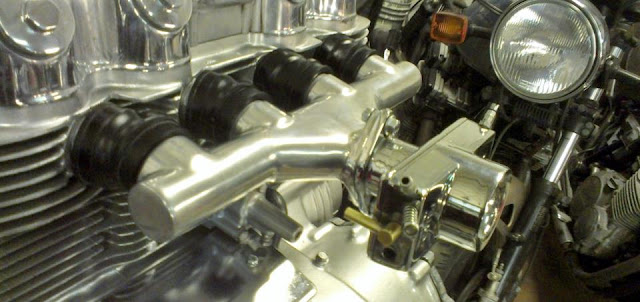

This POSA carburetor was originally used on motorcycles. The fuel tank on a motorcycle has a maximum of about 6" drop from the tank to the carb. On most VW powered aircraft with a full tank of fuel, there is about 12" maximum fuel drop. The point being that these styles of carburetors were designed to be operated on gravity fuel pressure only, and not much at that. I have seen fancy designs for fuel pressure regulators to be used with return lines etc, but have yet in 30 years seen a successful installation of a POSA style carb that ran correctly with a pressure regulator.

A few facts to consider

1" of fuel head is equal to .022 psi

46.17" inches of vertical fuel column is equal to 1 psi

Fuel boils at 170 degrees F

An average engine will consume between .435 and .450 lb. of fuel per hp per hour

Cowling air typically runs 60 F warmer than outside ambient air temperature, with isolated hotter spots.

A fuel system must have an adequate fuel vent.

Types of carb are float bowl, diaphragm, and floatless

Aircraft carbs, Zenith, Bing, Weber, Solex are examples of float bowl carbs. These carbs can operate on gravity feed or usually up to 4 psi of fuel pressure. Most of these have a float bowl well vent to prevent vapor lock.

Tillitson, Ellison, Zama, are types of diaphragm carburetors. These carbs usually require some fuel pressure to operate correctly.

POSA, Lake Injector, Revflow and Aero Carb are floatless, diaphragm less carburetors. These carbs do not operate well on more than .5 lbs of fuel pressure; yes that is less than pound of fuel pressure. These carbs do not vent any fuel vapor that may form in the body to the venturi as there is not float bowl well or diaphragm vent.

If a vapor lock forms in the body of the carb or the fuel line preceding the carb, the engine will start to surge and eventually quit if the vapor lock cannot be moved through the carb. It requires the absence of heat to remove the vapor lock from POSA style carbs as fuel pumps are not used.

How to adjust the carb for all throttle positions

Tools needed:

Screwdriver

#16 nail sharpened

Small jar

Syringe or breaker graduated in cc's or ounces

Gloves

Small wood throttle blocks (you'll make these)

Fire extinguisher rated for fuel

Instruments needed

Manifold pressure gauge

EGT gauge or air/fuel ratio gauge

So you have followed the manufacturer's directions to adjust your POSA style carburetor but find that you still have rich or lean spots across the range of throttle and you're frustrated. The first thing you need to do is acquire some patience, because to set the carb correctly takes about 4 hours of measuring and tuning.

1. The fuel in the tank should be full. This is because a full tank of fuel will make the carb run richer and an almost empty tank will run leaner. Remember that you are operating on .022 pound of pressure per inch of vertical fuel column. So if you have 12" of vertical fuel drop, (this is from the top of the tank to the carb, not from the top of the tank to the bottom of the tank) with a full tank this is .022 x 12 = .265 psi or a little over " lb of fuel pressure. For simplicity say our tank is only 6" tall. If we have used a half a tank of fuel we now have used 3" of fuel and have a 9" drop to the carb. So, 9 x .022 = .198 lbs of fuel pressure. Less than a quarter of a pound.

2. You need to pick 6 throttle positions and be able to repeat the positions. Use idle, 1500, 2000, 2500, 3000, and wide open throttle. With the carb set as best as you can get it, make a stop block that you can put in the throttle so you can accurately repeat each position. The rpm will change when you adjust the carb down the road. We simply need to be able to repeat the position. I use a piece of wood that has a hole drilled through it that is the throttle shafts diameter. Split the piece of wood in the center of the hole. The length of the wood will vary for each throttle setting.

3. At each throttle setting, use the needle to adjust the carb so the engine runs that absolute best at each station, irregardless as to how it runs anywhere else. Make note of the manifold pressure and egt/or air fuel ratio when the carb is set for each station. Once you have a single station set perfectly with the needle, turn the fuel on and let fuel flow out of the carb in to the bowl for 1 minute. Measure the amount and record it next to the egt/air fuel ratio and manifold pressure reading.

4. Repeat step 3 for all 6 stations, recording manifold pressure and rpm along with egt/air fuel ratio. Measure fuel flow for each individual station and record the measurement.

Note: this process will consume about 1 gallon of fuel. You need to keep the fuel in the tank as close to a constant fuel level as possible.

5. Now that you have made a chart that show the fuel flow out of the carb at each station where you set the carb so that the engine ran it's best, you need to set the needle so the carb runs the best at idle once aging. This will be the permanent setting for the needle. Idle position to about 1500 rpm is the most important throttle range. When you are coming down final you cannot have your engine quit. Likewise if you need to do a go around, you cannot have your engine stumble when you advance the throttle.

6. Now go back to each throttle position using your blocks of wood and re-measure the fuel out of the carb. In most cases it will be less than you originally measured it. So to bring the fuel flow up the same level you make a vertical mark along the flat of the needle where the needle goes into the fuel orifice. Just use a black fine line marker to do this.

Remove the needle. Now use the sharp nail and make a scratch mark along the horizontal axis of the needle 1/8" on both sides of the vertical mark. When satisfied with the depth, reinstall the needle and measure the fuel flow. You want it to be equal to what it was in steps #3 and 4.

This is the trial and error time consuming part of the job. Be cautioned that a little scratch for starters is better than a deep one. It does not take a very deep mark to allow a lot more fuel to flow.

When you are done with each station you will have a series of scratched that are not connected. You may find that in some areas of the needle you won't have to do much and in others you will have to have a deep scratch and you may need to connect the scratches with another scratch.

The top and bottom ends are critical. For the top end or wide open throttle, this is where the egt comes in handy. At wide open throttle, the engine should run about 50 to 100 degrees rich of peak. When you throttle back to 75% (23 inches of manifold pressure) power the egt should rise. Bear in mind that the rpm's vs. manifold pressure will be different on the ground than in the air with a loaded propeller.

When set correctly, you should be able to see a steady rise in the egt from idle to just before full power. At full power, the egt should dip slightly.

When you are in cruise mode with your VW, you want to run at 23" of manifold pressure, regardless of rpm. This is 75% power and is the best way to tell if you have the correct prop for your aircraft. Generally, higher speed aircraft like the KR, Sonerai and Sonex use a 52" to 54" diameter prop. You will usually see a cruise rpm of about 3000 to 3200 rpm and 23 inches of manifold pressure. Slower aircraft like the Preceptor Pups, use a diameter of 60" to 62" and corresponding 2800 to 3000 rpm at 23 inches of manifold pressure.

Note: in the event that the needle is rich at the bottom end instead of lean over the range, you will have to go to the next smallest needle and start the procedure again. It is very difficult to make a needle leaner with out adding material to the needle.

On POSA style carbs equipped with mixture control, set the mixture control so that is just shy of being full rich when doing the above needle work. In the event that you need to make the carburetor slightly richer, you can do so without having to go through the entire measure, scratch, measure, scratch scenario all over again. As you burn off fuel, the fuel pressure is less so you may need to go "over rich" to compensate for less pressure. HOW TO ADUST POSA STYLE CARBURETORS

Tags

autoblog | motorcycles| motorsports | youtube | horsepower | autos | auto

HOW TO ADUST POSA STYLE CARBURETORS

POSA Style carburetors trace their history back to the late 60's and early 70's. One of the first carburetors of this style was the Lake Injector. Don't confuse the word "injector" with fuel injection, as these series of carburetors are not a fuel injector or fuel injector body. During this same time period the POSA carburetors were introduced. As the POSA is a casting and the Lakes was a machined product, the Lake soon disappeared as the POSA was less expensive, buy a large margin.

The POSA was originally sold for aircraft use by HAPI, Revmaster and Monnett Experimental Aircraft. A little later in history, Revmaster introduced the Revflow Carburetor which is a similar type carburetor also. It looks like it might be a modified Lectron Carburetor body, with their own casting on one side of it with mixture control built into it.

The newest version of the POSA is the Aero Carb. Where as the POSA was a casting, the Aero Carb is machined from a billet of aluminum. The operational principals of all 4 carbs (Lake, POSA, Revflow and Aero Carb) are identical with variations in mixture control and needle adjustments for setting the mixture

All of these carbs have different needles that are round but have a flat ground on one side that is also tapered. As the throttle is opened, the needle is pulled out of a fuel orifice with the slide, allowing more fuel to be pulled into the carburetor throat. It is imperative that the flat part of the needle always face into the back of the carburetor.

If the needle were allowed to rotate, the draw across the needle changes and less fuel is induced into the engine, causing an engine to run lean. Most manufacturers of this style carburetor send a number of different needles along with the carburetor. The needles have different flats ground along the taper, allowing more or less fuel to be induced to the engine.

This POSA carburetor was originally used on motorcycles. The fuel tank on a motorcycle has a maximum of about 6" drop from the tank to the carb. On most VW powered aircraft with a full tank of fuel, there is about 12" maximum fuel drop. The point being that these styles of carburetors were designed to be operated on gravity fuel pressure only, and not much at that. I have seen fancy designs for fuel pressure regulators to be used with return lines etc, but have yet in 30 years seen a successful installation of a POSA style carb that ran correctly with a pressure regulator.

A few facts to consider

1" of fuel head is equal to .022 psi

46.17" inches of vertical fuel column is equal to 1 psi

Fuel boils at 170 degrees F

An average engine will consume between .435 and .450 lb. of fuel per hp per hour

Cowling air typically runs 60 F warmer than outside ambient air temperature, with isolated hotter spots.

A fuel system must have an adequate fuel vent.

Types of carb are float bowl, diaphragm, and floatless

Aircraft carbs, Zenith, Bing, Weber, Solex are examples of float bowl carbs. These carbs can operate on gravity feed or usually up to 4 psi of fuel pressure. Most of these have a float bowl well vent to prevent vapor lock.

Tillitson, Ellison, Zama, are types of diaphragm carburetors. These carbs usually require some fuel pressure to operate correctly.

POSA, Lake Injector, Revflow and Aero Carb are floatless, diaphragm less carburetors. These carbs do not operate well on more than .5 lbs of fuel pressure; yes that is less than pound of fuel pressure. These carbs do not vent any fuel vapor that may form in the body to the venturi as there is not float bowl well or diaphragm vent.

If a vapor lock forms in the body of the carb or the fuel line preceding the carb, the engine will start to surge and eventually quit if the vapor lock cannot be moved through the carb. It requires the absence of heat to remove the vapor lock from POSA style carbs as fuel pumps are not used.

How to adjust the carb for all throttle positions

Tools needed:

Screwdriver

#16 nail sharpened

Small jar

Syringe or breaker graduated in cc's or ounces

Gloves

Small wood throttle blocks (you'll make these)

Fire extinguisher rated for fuel

Instruments needed

Manifold pressure gauge

EGT gauge or air/fuel ratio gauge

So you have followed the manufacturer's directions to adjust your POSA style carburetor but find that you still have rich or lean spots across the range of throttle and you're frustrated. The first thing you need to do is acquire some patience, because to set the carb correctly takes about 4 hours of measuring and tuning.

1. The fuel in the tank should be full. This is because a full tank of fuel will make the carb run richer and an almost empty tank will run leaner. Remember that you are operating on .022 pound of pressure per inch of vertical fuel column. So if you have 12" of vertical fuel drop, (this is from the top of the tank to the carb, not from the top of the tank to the bottom of the tank) with a full tank this is .022 x 12 = .265 psi or a little over " lb of fuel pressure. For simplicity say our tank is only 6" tall. If we have used a half a tank of fuel we now have used 3" of fuel and have a 9" drop to the carb. So, 9 x .022 = .198 lbs of fuel pressure. Less than a quarter of a pound.

2. You need to pick 6 throttle positions and be able to repeat the positions. Use idle, 1500, 2000, 2500, 3000, and wide open throttle. With the carb set as best as you can get it, make a stop block that you can put in the throttle so you can accurately repeat each position. The rpm will change when you adjust the carb down the road. We simply need to be able to repeat the position. I use a piece of wood that has a hole drilled through it that is the throttle shafts diameter. Split the piece of wood in the center of the hole. The length of the wood will vary for each throttle setting.

3. At each throttle setting, use the needle to adjust the carb so the engine runs that absolute best at each station, irregardless as to how it runs anywhere else. Make note of the manifold pressure and egt/or air fuel ratio when the carb is set for each station. Once you have a single station set perfectly with the needle, turn the fuel on and let fuel flow out of the carb in to the bowl for 1 minute. Measure the amount and record it next to the egt/air fuel ratio and manifold pressure reading.

4. Repeat step 3 for all 6 stations, recording manifold pressure and rpm along with egt/air fuel ratio. Measure fuel flow for each individual station and record the measurement.

Note: this process will consume about 1 gallon of fuel. You need to keep the fuel in the tank as close to a constant fuel level as possible.

5. Now that you have made a chart that show the fuel flow out of the carb at each station where you set the carb so that the engine ran it's best, you need to set the needle so the carb runs the best at idle once aging. This will be the permanent setting for the needle. Idle position to about 1500 rpm is the most important throttle range. When you are coming down final you cannot have your engine quit. Likewise if you need to do a go around, you cannot have your engine stumble when you advance the throttle.

6. Now go back to each throttle position using your blocks of wood and re-measure the fuel out of the carb. In most cases it will be less than you originally measured it. So to bring the fuel flow up the same level you make a vertical mark along the flat of the needle where the needle goes into the fuel orifice. Just use a black fine line marker to do this.

Remove the needle. Now use the sharp nail and make a scratch mark along the horizontal axis of the needle 1/8" on both sides of the vertical mark. When satisfied with the depth, reinstall the needle and measure the fuel flow. You want it to be equal to what it was in steps #3 and 4.

This is the trial and error time consuming part of the job. Be cautioned that a little scratch for starters is better than a deep one. It does not take a very deep mark to allow a lot more fuel to flow.

When you are done with each station you will have a series of scratched that are not connected. You may find that in some areas of the needle you won't have to do much and in others you will have to have a deep scratch and you may need to connect the scratches with another scratch.

The top and bottom ends are critical. For the top end or wide open throttle, this is where the egt comes in handy. At wide open throttle, the engine should run about 50 to 100 degrees rich of peak. When you throttle back to 75% (23 inches of manifold pressure) power the egt should rise. Bear in mind that the rpm's vs. manifold pressure will be different on the ground than in the air with a loaded propeller.

When set correctly, you should be able to see a steady rise in the egt from idle to just before full power. At full power, the egt should dip slightly.

When you are in cruise mode with your VW, you want to run at 23" of manifold pressure, regardless of rpm. This is 75% power and is the best way to tell if you have the correct prop for your aircraft. Generally, higher speed aircraft like the KR, Sonerai and Sonex use a 52" to 54" diameter prop. You will usually see a cruise rpm of about 3000 to 3200 rpm and 23 inches of manifold pressure. Slower aircraft like the Preceptor Pups, use a diameter of 60" to 62" and corresponding 2800 to 3000 rpm at 23 inches of manifold pressure.

Note: in the event that the needle is rich at the bottom end instead of lean over the range, you will have to go to the next smallest needle and start the procedure again. It is very difficult to make a needle leaner with out adding material to the needle.

On POSA style carbs equipped with mixture control, set the mixture control so that is just shy of being full rich when doing the above needle work. In the event that you need to make the carburetor slightly richer, you can do so without having to go through the entire measure, scratch, measure, scratch scenario all over again. As you burn off fuel, the fuel pressure is less so you may need to go "over rich" to compensate for less pressure. HOW TO ADUST POSA STYLE CARBURETORS

Tags

autoblog | motorcycles| motorsports | youtube | horsepower | autos | auto

.jpg)

0 comments:

Post a Comment